Zdenek’s Story from the Czech Factory

If you’ve ever ridden a bike, chances are SHIMANO was right there with you.

You might not have noticed it, but every smooth gear change and effortless pedal stroke is made possible by SHIMANO working quietly behind the scenes. For hundreds of millions of cyclists around the world, SHIMANO is an essential part of the ride.

Photo by streetsh on Unsplash

As a global manufacturing powerhouse, SHIMANO runs production facilities all over the world.

One of SHIMANO’s key facilities—a factory in the Czech Republic—has been operating continuously for over two decades, playing a vital role in its global production network.

Here, precision and efficiency are part of the culture. Every screw, every step in the process is executed with standardized workflows and attention to detail.

At the center of today’s story is Zdenek, a seasoned engineer who’s spent years at this Czech facility—and recently, he’s begun exploring a new way to build: without code.

Zdenek, the Engineer at SHIMANO

Zdenek’s No-Code Journey

While Zdenek’s official role is overseeing assembly line processes, that’s just a small part of what he does each day. As a process engineer, he plays a key role in driving continuous improvement across the factory—from digital transformation initiatives to boosting production efficiency and enhancing workplace safety.

He used to collaborate closely with the IT department, co-developing internal systems and streamlining workflows. But once the factory fully transitioned to SAP, the IT team’s focus shifted to maintaining core infrastructure. As a result, many internal tooling needs were left unmet.

“We had plenty of needs, but IT was too busy—there were a lot of issues we just couldn’t fix.” —Zdenek

With growing frustration over messy Excel files and labor-intensive workflows, Zdenek decided to take action himself.

He began exploring no-code platforms, aiming to bypass the coding barrier and empower engineers on the ground to build solutions on their own.

His first stop was Power Apps. On paper, it seemed like an enterprise-grade solution within the Microsoft ecosystem. But once he started using it, the experience was far from smooth: the UI logic wasn’t intuitive, permission settings were overly complex, and even minor changes required IT approval. What frontline engineers needed was speed and autonomy.

That’s when he came across NocoBase—a discovery that would fundamentally change his approach.

With no license fees and no reliance on complex IT setups, NocoBase gave Zdenek exactly what he needed: the power to build, adapt, and improve systems independently. For the first time, he could turn ideas into working tools—without writing a single line of code.

From Excel to Integrated Systems

Initially, Zdenek simply wanted to solve a very specific problem: how to streamline the ISO audit process.

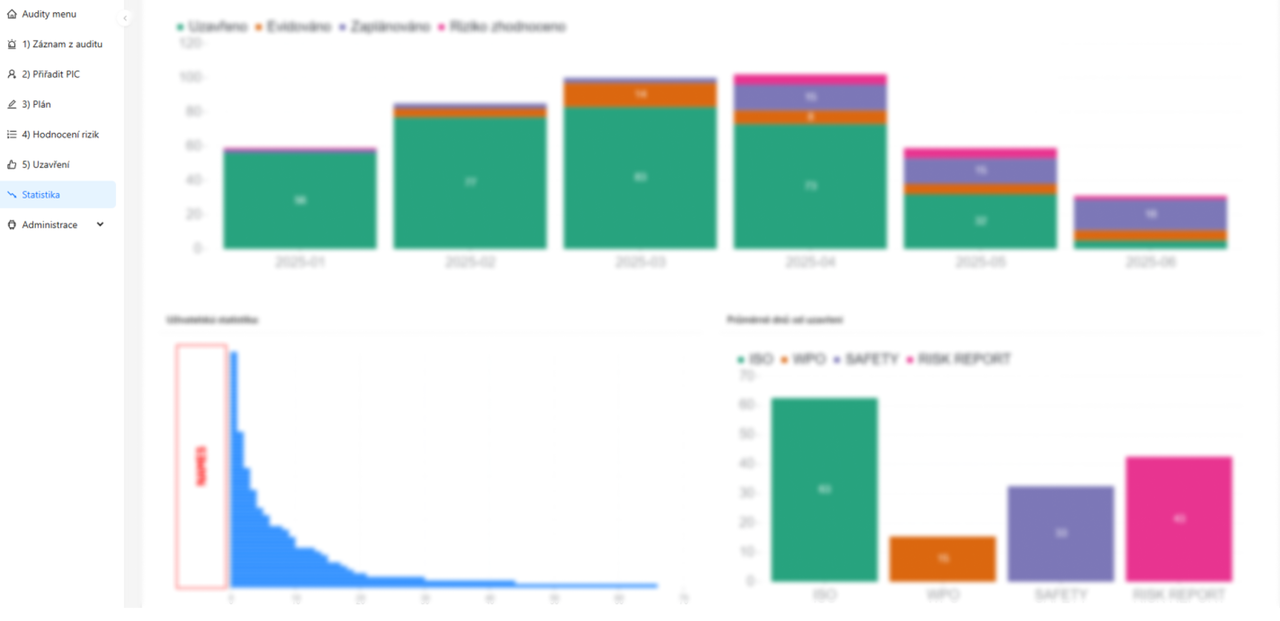

Using NocoBase, they developed their first system: the Audit App. This application seamlessly connected every stage of the audit workflow, from “Evidence Collection” to “Closing.” While initially used only for recording and tracking audit items, Zdenek progressively enhanced the system with more features as its use deepened:

- User notification mechanisms that immediately alert responsible parties.

- A public form portal allowing frontline employees to directly report risks.

- Delegation of audit report responsibilities (Report Delegation), significantly improving completion rates.

“We no longer need to constantly chase people down; every record now has a clear process and designated owner,” Zdenek stated.

Audit App Dashboard

The successful implementation of this system broadened Zdenek’s perspective. If one system could be built, why not more? He began systematically migrating other Excel-managed forms and processes within the factory to NocoBase.

Over the following weeks, Zdenek developed several additional systems:

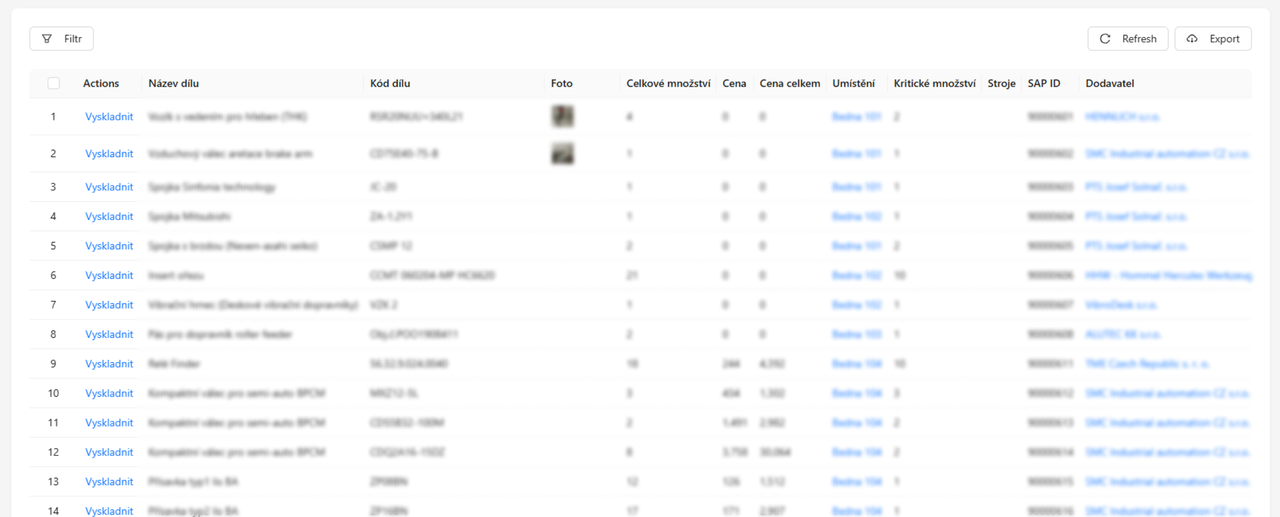

- A spare parts inventory management system to track the inflow, outflow, and stock changes of components, significantly reducing manual errors and optimizing stock levels.

- A document approval system to standardize file circulation, ensuring consistent workflows and faster approvals.

- A task list module for assigning work items to individuals, helping departments monitor progress.

- An equipment approval system for managing equipment usage and authorization requests.

- A mobile inspection tool enabling frontline staff to complete forms and submit data directly from their phones.

“The most surprising part was how intuitive it was; users could pick it up almost without any training,” Zdenek remarked.

Spare parts evidence (store out)

With NocoBase’s flexible setup options and role-based controls, they could tailor each interface to the exact needs of different teams. What truly amazed him, however, was its automated workflow configuration. This enabled features like automatic reminders for responsible parties during audits, notifications sent before task deadlines, and even seamless data transfer across different forms.

Throughout this entire process, Zdenek leveraged a flexible no-code tool to transform previously unaddressed needs for small tools into genuinely functional systems, all without traditional programming.

“My first impression was ‘Wow.’ Data entry and processing became incredibly simple,” Zdenek said.

Factory users quickly adapted to the new systems. They no longer worried about formatting errors or spending time searching for misplaced files. The clear interface, granular permission settings, and mobile support empowered frontline employees to truly integrate the tools into their daily work. From a management perspective, capabilities like audit logs, field-level control, and workflow automation ensured the stability and security of their processes.

Zdenek and his colleagues are now planning to build even more frontline tools using NocoBase, from production scheduling to equipment maintenance, continually unlocking processes that were once stalled due to a lack of coding resources.

Key Takeaways

With limited resources, Zdenek discovered a lighter, more efficient, and fully controllable approach to digitalization. Although he’s not a developer, his no-code efforts have genuinely reshaped the internal management methods at Shimano’s Czech factory.

Zdenek’s story shows that true digital transformation isn’t reserved for developers—it begins when those closest to the work are given the power to improve it.

This perfectly exemplifies NocoBase’s typical application in manufacturing: enabling those who understand the business to directly transform their processes into practical tools.

The cover image of the article is by David Dvořáček on Unsplash.

More Customer Stories:

- What made Japan’s leading real estate firm switch from Salesforce to open-source NocoBase?

- How Second-Brain built an AI system for financial institutions with NocoBase

- How the No.1 AI Voice Recorder Brand Built Its Internal Systems

- Beyond Spreadsheets: Classmethod’s Employee Data Management with NocoBase

- How One Furniture Factory Built Its Own ERP—No Coding Needed

- From Designer to Builder: L&A’s Digital Transformation with NocoBase