Here’s how Okechamp and Lukardi used NocoBase to transform supply chain operations.

About Okechamp and Lukardi

In Europe’s mushroom industry, Okechamp is everywhere—from the farm to your plate.

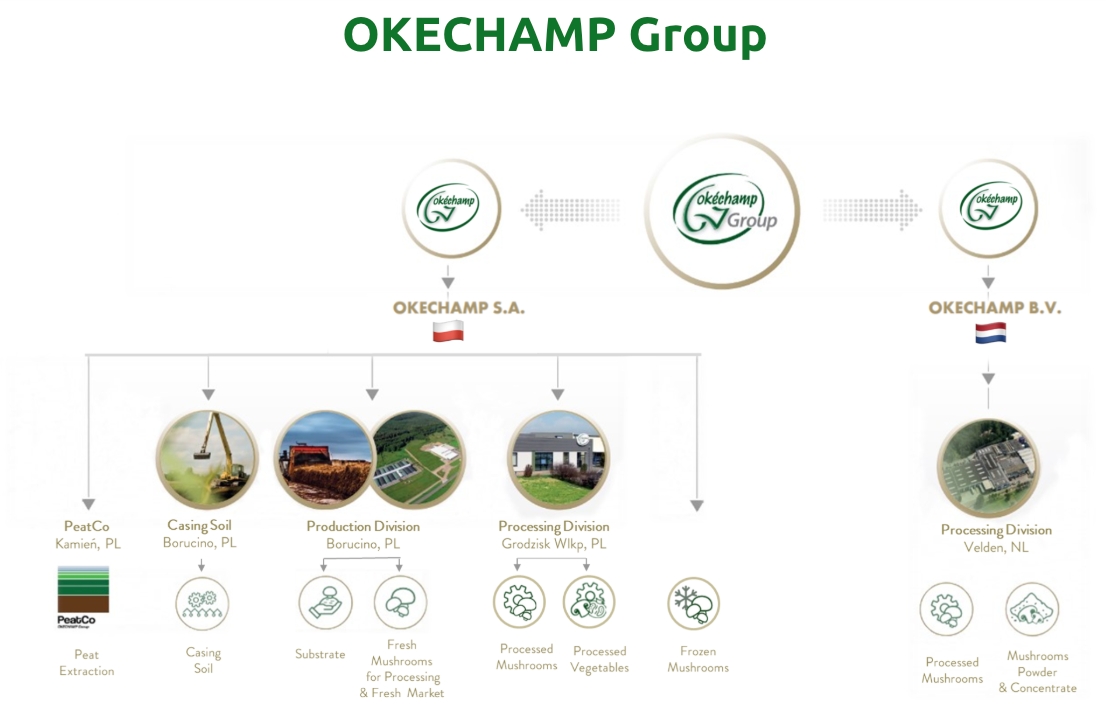

Headquartered in Poland, this food giant is one of the continent’s top mushroom producers and processors. Every year, Okechamp handles and delivers tens of thousands of tons of mushrooms to markets around the world. Its operations cover everything from cultivation and processing to end distribution, all under strict standards for sustainability and food quality.

For a company of this scale operating across Europe, even the slightest delay in logistics can ripple across the entire supply chain. As their business kept expanding, Okechamp began searching for smarter, more efficient solutions.

That’s when they turned to Lukardi—a Polish tech company specializing in enterprise digital transformation. Lukardi’s services span SAP implementation, document management, cybersecurity, and building business systems using no-code and low-code platforms.

Optimizing Logistics Scheduling

As Okechamp scaled its operations across Poland and the Netherlands, coordinating logistics became increasingly complex.

In Poland, the company manages peat extraction, fresh mushroom farming, and primary processing. Meanwhile, its Dutch facilities focus on advanced processing and mushroom concentrate production. Together, they form an end-to-end supply chain—from cultivation to distribution.

Every day, large volumes of goods move between these sites, putting intense pressure on the company’s ability to schedule and coordinate logistics efficiently.

Before upgrading their system, Okechamp struggled with four major pain points:

- Disconnected warehouses with no centralized view, leading to scattered and inefficient scheduling

- Manual coordination of loading dock times, causing frequent clashes

- No real-time visibility into dock availability, making last-minute changes nearly impossible

- Slow communication between drivers, coordinators, and teams, delaying operations

To solve these issues, Okechamp brought in Lukardi to build a custom logistics scheduling system—one that could centralize planning, visualize operations, and intelligently automate the entire dispatch workflow.

Scheduling System Live in 6 Weeks

After reviewing the requirements, Lukardi opted to build the entire system using NocoBase. Its schema-first architecture and plugin-based design significantly boosted development efficiency and delivery flexibility compared to traditional methods.

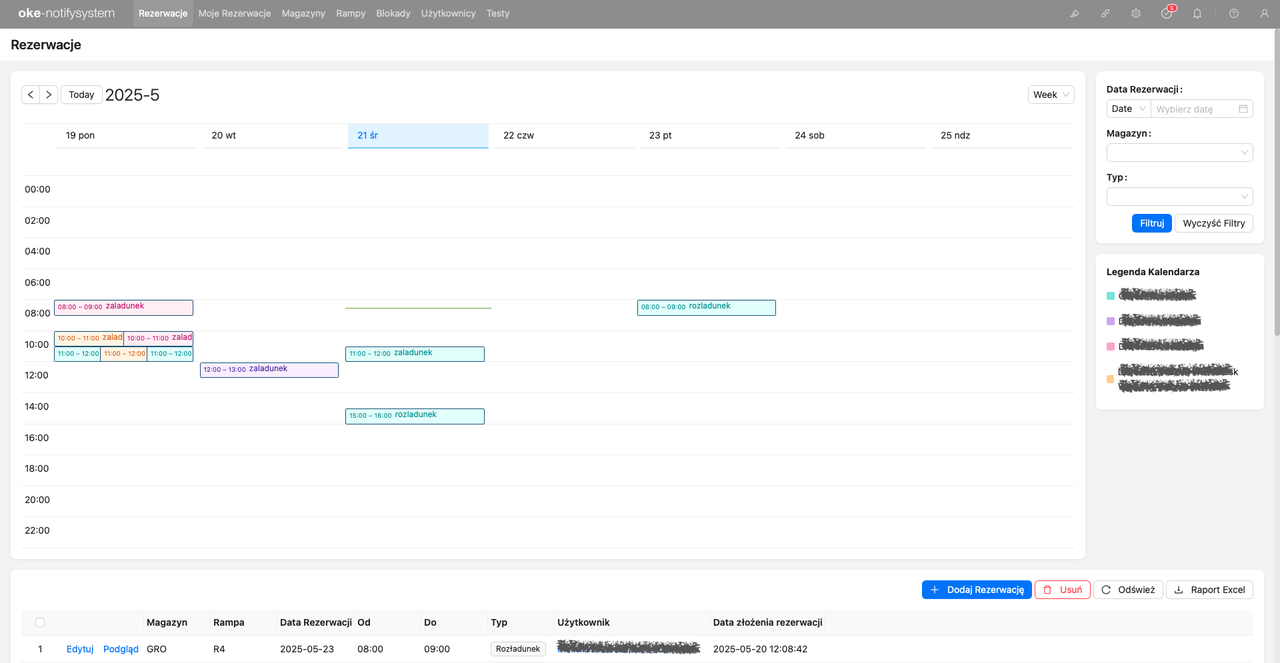

In under six weeks, a custom loading and unloading bay appointment and scheduling system specifically for Okechamp was launched and operational. The system boasts two core functionalities:

1. Loading Bay Appointment Application

Users can book loading dock slots by selecting cargo type, warehouse location, and time range. The system checks for conflicts and auto-assigns available slots. It’s easy to use, cuts coordination effort, and dramatically improves loading efficiency.

2. Platform Management and Backend Access Control

With multi-role logins and fine-grained permission controls, each user—whether a scheduler, warehouse manager, or driver coordinator—sees only what they need. This keeps workflows safe, organized, and team-friendly.

From Lukardi’s perspective, these design decisions made this rapid success possible:

- Scalable from Day One

NocoBase’s flexible architecture provided the system with inherent scalability from the outset. This not only meets current multi-warehouse collaboration needs but also allows ample room for future feature iterations.

- Custom Reporting & Daily View

Custom views give frontline teams a clear picture of their daily tasks and dock availability—speeding up decisions and actions.

Project Outcomes: Expedited Logistics Scheduling

Once the new system launched, Okechamp’s logistics team could finally breathe easier.

Gone were the days of messy schedules and endless back-and-forth—everything was now handled through a streamlined, visual system. Dispatchers had instant visibility into every loading dock. Changes, reminders, and confirmations were just a click away. And for the first time, frontline teams had their own “digital calendar”—with daily tasks delivered straight from the system, no more relying on verbal updates.

Built by Lukardi with NocoBase, the system brought measurable gains in efficiency:

- Over 70% reduction in scheduling coordination time

- Zero scheduling conflicts

- Full-process visualization for over 50 users

- Faster supplier response and improved cooperation

What really convinced Lukardi of NocoBase’s long-term value was its technical foundation:

- The clarity and structured approach offered by the schema-first modeling.

- The multi-role permission control mechanism, ensuring orderly processes during large-team collaborations.

- The plugin architecture, which enables rapid integration and on-demand customization.

- Multi-language support, facilitating system expansion into broader international markets.

Today, this system reliably supports Okechamp’s daily operations, and Lukardi views this as just the beginning. Given the success of this collaboration, they plan to establish NocoBase as a core platform for future enterprise projects.

Conclusion

Not long ago, building a system like this would have taken months—and a full in-house dev team to make it happen.

But with the rise of open-source platforms and expert service providers, companies now have a faster, leaner way to go digital.

More firms like Lukardi are making NocoBase a core part of their delivery stack—creating tailored solutions for everything from internal tools to customer-facing platforms, across all kinds of industries.

That’s exactly what we set out to achieve with NocoBase: helping skilled teams deliver real, complex solutions with fewer resources.

And we can’t wait to see more NocoBase-powered systems go live, solving tough problems in real-world settings.

More Customer Stories:

- BIEL Crystal’s Digital Factory: Powering 1.85 Billion Units a Year

- How Distinct HealthCare Uses NocoBase to Build a Personalized, Long-Term Care System

- A No-Code Journey Inside SHIMANO

- What made Japan’s leading real estate firm switch from Salesforce to open-source NocoBase?

- How Second-Brain built an AI system for financial institutions with NocoBase

- How the No.1 AI Voice Recorder Brand Built Its Internal Systems